Strong neodymium bar magnets are often used in industry and life, mainly in electronics, electrical appliances, packaging, motors, toys, leather goods, automotive machinery and other fields. Under normal circumstances, NdFeB magnets can pick up objects 600 times their own weight. The suction force of NdFeB magnets has a certain relationship with its volume, performance grade and distance. The higher the grade, the greater the suction power. For example, the magnet of the same size and specification, N48 has a much higher suction power than N35. Refers to the distance between the magnet and the object to be adsorbed. The greater the distance, the smaller the suction force. There are many specifications of NdFeB magnets, including holes and special-shaped ones, which are directly related to the suction force, and the calculation is more complicated. And different distances have different suction power. Different material grades also have different suction power. But few people know the types and shapes of NdFeB magnets.

According to the production process attributes of NdFeB magnets, the types of strong neodymium bar magnets can generally be divided into two categories: bonded NdFeB magnets and sintered NdFeB magnets. The so-called bonded NdFeB magnet process is actually injection molding; while the process principle of sintered NdFeB magnet is to extract vacuum and form by high temperature heating.

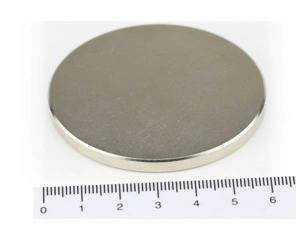

1. Circle neodymium magnets

Circle neodymium magnets include: cylindrical, circular, hole-shaped, disc-shaped, oval, etc.

2. Square NdFeB magnet

Square magnets include: square, rectangle, strip, square, etc.

3. Arc NdFeB magnets

Arc magnets include: arc, tile, semicircle, etc.

4. Special-shaped NdFeB magnets

Special-shaped magnets include: pie-shaped, hoof-shaped, trapezoidal, convex, countersunk, etc.

Neodymium iron boron magnets are particularly strong, and it is necessary to prevent hands or other parts of the body from being clamped by the magnets. Do not place strong magnets near electronic medical devices or patients with devices such as pacemakers. Do not swallow strong magnets. If the magnet manufacturer accidentally swallows it, seek medical attention immediately. Strong magnets should be kept out of the reach of children.

In the use of magnets, the environment should be kept as clean as possible to prevent fine impurities such as iron filings from being adsorbed on the surface of the magnet and affecting the use. Magnetic shavings fly into the eyes, causing damage and must be handled with care. NdFeB magnets should be stored in a ventilated and dry environment. Acidic, alkaline, organic solvents, salt water, high temperature and humid environments will easily oxidize the magnets, the electroplating layer will fall off, and the magnets will be pulverized and demagnetized.

After the magnet is heated at high temperature, the magnetic function will be attenuated. Please refer to the temperature resistance guidelines for the corresponding functions of the magnet. The magnet manufacturer pays attention not to overheat the working temperature when the magnet is assembled or used. NdFeB magnets are brittle, so when they are used for vibration, shock, etc., they may crack and fall. Be careful of bumps in use.