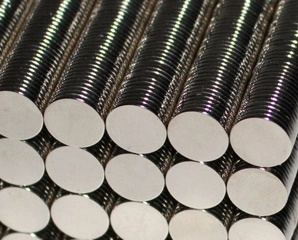

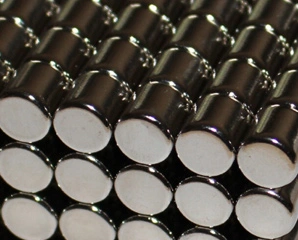

NdFeB is a tetragonal crystal formed by neodymium, iron and boron. NdFeB magnets are widely used in electronics, electrical machinery, medical equipment, toys, packaging, hardware machinery, aerospace and other fields. Magnetic motors, speakers, magnetic separators, computer disk drives, magnetic resonance imaging equipment meters, etc.

In order to avoid corrosion damage, NdFeB magnets need to be protected on the surface of the permanent magnet material during use, such as electroplating with gold, nickel, zinc, and tin, and spraying epoxy resin on the surface. NdFeB magnets are divided into sintered NdFeB magnets and bonded NdFeB magnets. Bonded NdFeB magnets are magnetic in all directions and are resistant to corrosion; while sintered NdFeB magnets are prone to corrosion and require coating on the surface. Zinc, nickel, environmental protection zinc, environmental protection nickel, nickel copper nickel, environmental protection nickel copper nickel, etc. Sintered NdFeB is generally divided into axial magnetization and radial magnetization, which are determined according to the required working surface.

After the strong NdFeB magnet is applied for a period of time, the smooth shape will gradually appear milky white or other color spots, and gradually widen will produce rust. Generally speaking, the coating of waterproof neodymium magnet is not so easy to be rusted. Rust corrosion damage of NdFeB magnets is mostly due to the following conditions:

1. Before electroplating, the NdFeB magnets did not completely clean the dirt on the surface.

2. The outer packaging plastic bag of the NdFeB magnet is not well sealed, causing the magnet to be oxidized in air.

3. The duration of the electroplating process is not up to standard or there are technical problems.

4. The site where NdFeB magnets are stored has high humidity, poor indoor ventilation, and great changes in temperature; the key to preventing NdFeB magnets from rusting is to store them in a cool and dry place depending on their placement.

Due to the increase in demand for new energy vehicles, industrial machines, wind power generation and energy-saving motors, enterprises' purchase demand for NdFeB will also increase significantly, which will also lead to a strong and high price of rare earth. Now affected by the general market environment, the first half of the year is a low season for sales, and the market is basically rejuvenated in the second half of the year. The sales of NdFeB magnets are expected to usher in good news. Many enterprises engaged in the production and customization of NdFeB magnets have also begun to actively prepare rare earth materials. and talents to expand production capacity. With the improvement of the quality requirements of NdFeB magnets in the market, many rare earth enterprises are also transforming and upgrading in order to improve the market competitiveness of their products. From the perspective of international market demand, the demand for NdFeB magnets in Japan is increasing, which will benefit from the accelerated industry reshuffle under the conditions of energy saving and environmental protection. Many companies are actively developing new energy technology.