The flat and round shape strong NdFeB magnets are give the name of disc neodymium(NdFeB) strong magnets, the size of diameter is larger than its thickness.

View More

Explore our range of rare earth neodymium ring magnets, available in various sizes and grades. From tiny 5mm to larger 30mm outer diameter magnets, we offer versatile options for your magnetic needs.

View More

Experience magnetic innovation with strong rectangular rare earth magnets - versatile and powerful, perfect for creative experiments and practical applications.

View More

Cylinder neodymium magnets are powerful rare-earth magnets with a cylindrical shape, known for their exceptional strength and versatility.

View More

Meank Magnet provides neodymium countersunk magnets available in various sizes and shapes to suit your specific needs.

View More

Explore the strength and versatility of neodymium ball magnets. Perfect for scientific exploration, toys, and medical applications, delivering precision and creativity.

View More

Neodymium cube magnets, small yet potent, offer versatile solutions for various applications. Explore their compact strength at Meank.

View More

Rare earth neodymium cone magnets: precision-engineered for versatile applications, these custom magnets redefine performance, providing unmatched reliability and efficiency in diverse industrial and creative settings.

View More

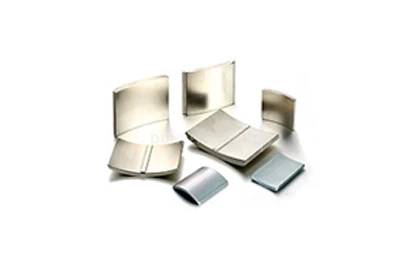

Neodymium Arc Magnets - powerful and customizable magnetic solutions for diverse applications, ensuring efficiency and reliability.

View More

Neodymium channel magnets are a type of strong magnet made from neodymium (NdFeB), which is the most powerful type of permanent magnet available. These magnets are encased in a steel channel, enhancing their magnetic force and durability.

View More

Adhesive magnets (also called as adhesive backed magnets) are magnets with 3M self-adhesive on one of magnetized surfaces. 3M self-adhesive magnets are usually used on the surface of non ferromagnetic objects. Disc self-adhesive magnets and rectangular self-adhesive magnet are the most common adhesive magnets.

View More In terms of shape, we have round, ring, square, countersunk, spherical, cylinder and other standard shapes of neodymium magnets for sale.

In terms of application, we, professional in neodymium magnets including n52 arc magnets and neodymium channel magnets, have strong neodymium magnets for mounting, fishing, holding and hanging, as well as high-performance neodymium magnets for other different high-tech fields.

In terms of size, we have mini very strong magnets for sale as small as 0.5mm and super large neodymium magnets as large as 250mm.

In terms of surface treatment, in addition to the high power magnets for sale with normal electroplating coating, we also have plastic, rubber, PVC and Teflon coated neodymium for sale.

In short, we have a very full range of strong neodymium magnets for sale.

With China's high-quality magnetic material resources, an experienced team of engineers and advanced processing equipment, we can customize special and irregular neodymium magnets, such as epoxy coated arc magnets and neodymium cone magnet, to meet your exact specifications. If you need special custom neodymium magnets or magnetic components, please contact us and send us a quotation request. We will help you determine the most economical solution for your project.

| Material | Remanence (Br) | HcB | HcJ | (B-H)max | Max.Temp. | ||||

| Type (Grade) | (KGs) | (mT) | (Koe) | (KA/m) | (Koe) | (KA/m) | (MGOe) | (KJ/m3) | ℃ |

| N35 | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥12 | ≥955 | 33-36 | 263-287 | 80℃ |

| N38 | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥12 | ≥955 | 36-39 | 287-310 | 80℃ |

| N40 | 12.5-12.8 | 1250-1280 | ≥11.4 | ≥907 | ≥12 | ≥955 | 38-41 | 302-326 | 80℃ |

| N42 | 12.8-13.2 | 1280-1320 | ≥11.5 | ≥915 | ≥12 | ≥955 | 40-43 | 318-342 | 80℃ |

| N45 | 13.2-13.8 | 1320-1380 | ≥11.6 | ≥923 | ≥12 | ≥955 | 43-46 | 342-366 | 80℃ |

| N48 | 13.8-14.2 | 1380-1420 | ≥10.5 | ≥836 | ≥12 | ≥955 | 46-49 | 366-390 | 80℃ |

| N50 | 14.0-14.5 | 1400-1450 | ≥10.0 | ≥796 | ≥11 | ≥876 | 48-51 | 382-406 | 80℃ |

| N52 | 14.3-14.8 | 1430-1480 | ≥10.0 | ≥796 | ≥11 | ≥876 | 50-53 | 398-422 | 60℃ |

| N54 | 14.5-15.1 | 1450-1510 | ≥10.0 | ≥796 | ≥11 | ≥876 | 50-53 | 398-422 | 60℃ |

| 33M | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥14 | ≥1114 | 31-33 | 247-263 | 100℃ |

| 35M | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥14 | ≥1114 | 33-36 | 263-287 | 100℃ |

| 38M | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥14 | ≥1114 | 36-39 | 287-310 | 100℃ |

| 40M | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥14 | ≥1114 | 38-41 | 302-326 | 100℃ |

| 42M | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥14 | ≥1114 | 40-43 | 318-342 | 100℃ |

| 45M | 13.2-13.8 | 1320-1380 | ≥12.5 | ≥995 | ≥14 | ≥1114 | 43-46 | 342-366 | 100℃ |

| 48M | 13.6-14.3 | 1360-1430 | ≥12.9 | ≥1027 | ≥14 | ≥1114 | 46-49 | 366-390 | 100℃ |

| 50M | 14.0-14.5 | 1400-1450 | ≥13.0 | ≥1033 | ≥14 | ≥1114 | 48-51 | 382-406 | 100℃ |

| 35H | 11.7-12.2 | 1170-1220 | ≥10.9 | ≥868 | ≥17 | ≥1353 | 33-36 | 263-287 | 120℃ |

| 38H | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥17 | ≥1353 | 36-39 | 287-310 | 120℃ |

| 40H | 12.5-12.8 | 1250-1280 | ≥11.6 | ≥923 | ≥17 | ≥1353 | 38-41 | 302-326 | 120℃ |

| 42H | 12.8-13.2 | 1280-1320 | ≥12.0 | ≥955 | ≥17 | ≥1353 | 40-43 | 318-342 | 120℃ |

| 45H | 13.2-13.6 | 1320-1360 | ≥12.1 | ≥963 | ≥17 | ≥1353 | 43-46 | 342-366 | 120℃ |

| 48H | 13.7-14.3 | 1370-1430 | ≥12.5 | ≥995 | ≥17 | ≥1353 | 46-49 | 366-390 | 120℃ |

| 35SH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥20 | ≥1592 | 33-36 | 263-287 | 150℃ |

| 38SH | 12.2-12.5 | 1220-1250 | ≥11.4 | ≥907 | ≥20 | ≥1592 | 36-39 | 287-310 | 150℃ |

| 40SH | 12.5-12.8 | 1250-1280 | ≥11.8 | ≥939 | ≥20 | ≥1592 | 38-41 | 302-326 | 150℃ |

| 42SH | 12.8-13.2 | 1280-1320 | ≥12.4 | ≥987 | ≥20 | ≥1592 | 40-43 | 318-342 | 150℃ |

| 45SH | 13.2-13.8 | 1320-1380 | ≥12.6 | ≥1003 | ≥20 | ≥1592 | 43-46 | 342-366 | 150℃ |

| 28UH | 10.2-10.8 | 1020-1080 | ≥9.6 | ≥764 | ≥25 | ≥1990 | 26-29 | 207-231 | 180℃ |

| 30UH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥25 | ≥1990 | 28-31 | 223-247 | 180℃ |

| 33UH | 11.3-11.7 | 1130-1170 | ≥10.7 | ≥852 | ≥25 | ≥1990 | 31-34 | 247-271 | 180℃ |

| 35UH | 11.8-12.2 | 1180-1220 | ≥10.8 | ≥860 | ≥25 | ≥1990 | 33-36 | 263-287 | 180℃ |

| 38UH | 12.2-12.5 | 1220-1250 | ≥11.0 | ≥876 | ≥25 | ≥1990 | 36-39 | 287-310 | 180℃ |

| 40UH | 12.5-12.8 | 1250-1280 | ≥11.3 | ≥899 | ≥25 | ≥1990 | 38-41 | 302-326 | 180℃ |

| 28EH | 10.4-10.9 | 1040-1090 | ≥9.8 | ≥780 | ≥30 | ≥2388 | 26-29 | 207-231 | 200℃ |

| 30EH | 10.8-11.3 | 1080-1130 | ≥10.2 | ≥812 | ≥30 | ≥2388 | 28-31 | 223-247 | 200℃ |

| 33EH | 11.3-11.7 | 1130-1170 | ≥10.5 | ≥836 | ≥30 | ≥2388 | 31-34 | 247-271 | 200℃ |

| 35EH | 11.7-12.2 | 1170-1220 | ≥11.0 | ≥876 | ≥30 | ≥2388 | 33-36 | 263-287 | 200℃ |

| 38EH | 12.2-12.5 | 1220-1250 | ≥11.3 | ≥899 | ≥30 | ≥2388 | 36-39 | 287-310 | 200℃ |

| 28AH | 10.4-10.9 | 1040-1090 | ≥9.9 | ≥787 | ≥33 | ≥2642 | 26-29 | 207-231 | 230℃ |

| 30AH | 10.8-11.3 | 1080-1130 | ≥10.3 | ≥819 | ≥33 | ≥2642 | 28-31 | 223-247 | 230℃ |

| 33AH | 11.3-11.7 | 1130-1170 | ≥10.6 | ≥843 | ≥33 | ≥2642 | 31-34 | 247-271 | 230℃ |

Note:

The above-mentioned magnetic performance dates are all given under room temperature.

The above-mentioned maximum working temperature of neodymium magnets is changeable due to the ratio of length and diameter,surface treatment and environmental factors.

All above mentioned magnetic property dates are just for reference.

![]()

Neodymium rare earth magnets are considered the strongest magnets because they have high saturation magnetization and the highest magnetic energy product. One of the main benefits of using neodymium magnets is that the size of the whole equipment can be minimized.

As long as the physical characteristics of neodymium magnets remain unchanged and are not affected by demagnetization (such as high temperature, reverse magnetic field, radiation, etc.), the loss of magnetic flux density of neodymium magnet may be less than 1% within 10 years.

Compared with other rare earth magnetic materials such as samarium cobalt magnets, neodymium magnets are not easy to crack and break, and the cost is low. However, they are more sensitive to temperature. For this critical application, samarium cobalt may be a better choice because its magnetism is very stable at high temperature.

Neodymium magnetic material can be made into many shapes,normally include disc magnets,ring&tube magnets,cylinder magnets,cone magnets,countersunk magnets,cube magnet,sphere magnets,rectangular&square magnet blocks.For special shapes that not shown on the website,please contact us for customizing.

Yes,neodymium magnets must be done with surface coating,any neodymium magnets without surface coating may rust in humid conditions.

The magnets which have magnetic fields that do not turn on and off like electromagnets are known as permanent magnets. We supply all kinds of permanent magnets, such as neodymium magnets, AlNiCo magnets, SmCo magnets, ferrite magnets and rubber magnets. Permanent magnets represent the majority of magnetic materials available today.

Permanent magnets are rated by their residual induction, coercive force & maximum energy product. This refers to the maximum strength that the magnetic material can be magnetized.

Neodymium magnets are hard, quite fragile and have high magnetic strength. They can bite together strongly, so please make sure that all personnel operating these magnets know to operate with care to avoid injury. If they fall or get stuck together, they can also break or break, so please be very careful when handling these powerful magnets!

Please fill the form to let us know your need. Our sales will get in touch with you ASAP.

1 FLOOR, NO.128 BUILDING-1 128#, JIJIN ROAD, XIAOGANG, BEILUN, NINGBO CITY, ZHEJIANG PROVINCE, CHINA